Living Pool construction methods

There are basically two types of Living Pool construction: the liner pool construction and the prefabricated pool construction. Budgets and necessary construction times significantly influence the choices made here, and must be taken into account from the planning stage.

Liner pools

This is the most commonly used construction method for Living Pools. A base plate is made onsite and a wall is built. The pool is then sealed using a polypropylene liner.

Prefabricated monopools

The Living Pool can also be delivered as a prefabricated monopool. In this case, a pit is excavated at the construction site and a concrete slab is cast as a foundation. This requires precise planning and preparation, but the short construction time, perfectly smooth surfaces and the monopool’s long lifespan are its distinct advantages. Furthermore, this construction method is ideal for organic pools, since monopools are very easy to clean.

The monopool is not made of the commonly used epoxy resin. Instead, polypropylene sheets are used. These sheets are welded together by the manufacturer beforehand, according to the dimensions and shapes required. This means the completed monopool can be transported to the customer in one piece. Thanks to the large variety of shape and design possibilities, there are no limits to your imagination—yet another advantage over epoxy resin pools.

Advantages

- Any shape or size is possible.

- Polypropylene, an environmentally friendly material, does not release any toxins.

- High quality finishing on all corners and edges

- Simple, quick installation with short on-site construction time

- Smooth surfaces simplify cleaning.

- 10-year warranty

Monopools can basically be divided into the three types overflow, infinity and skimmer. This makes them ideal for all different terrains and design requirements.

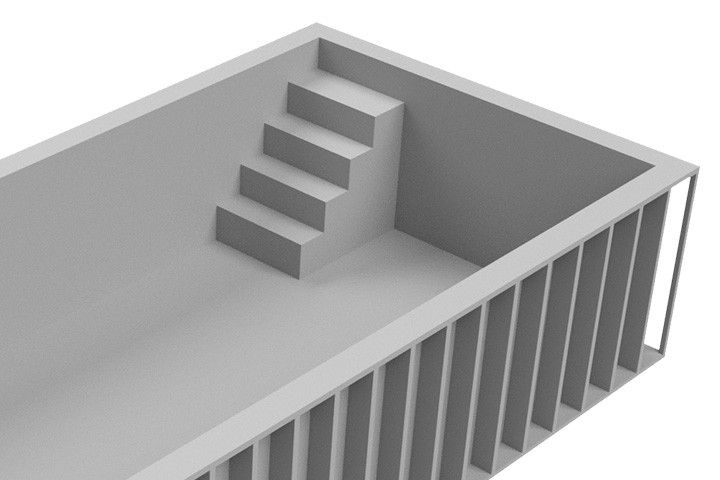

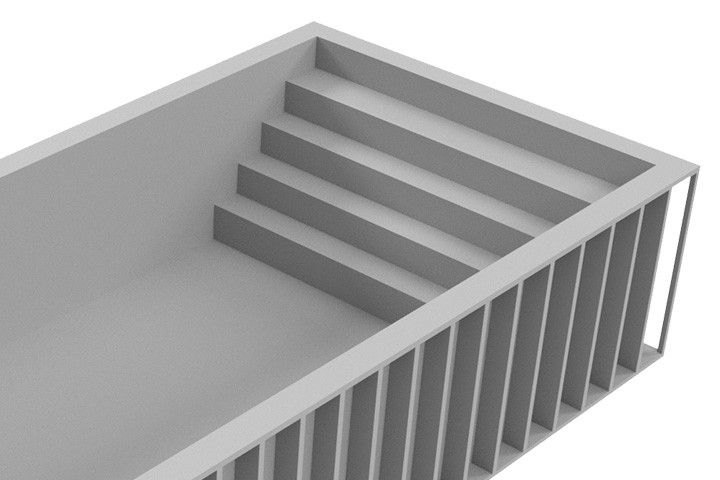

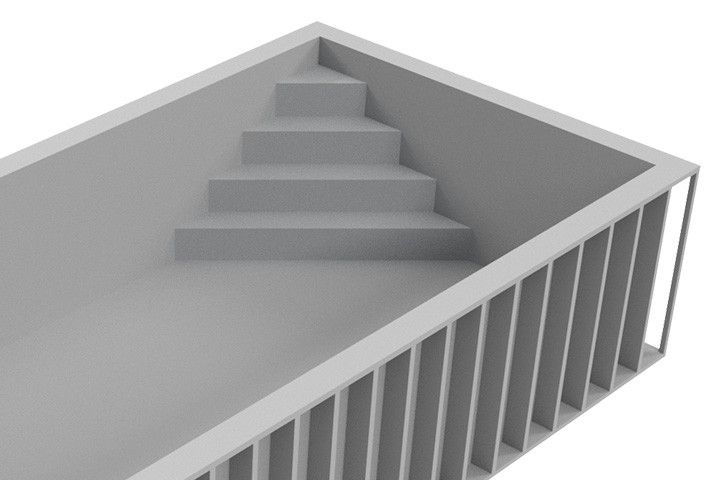

Staircases can be integrated into the pool directly during manufacture, or stainless steel ladders can be fitted later on. On top of the standard configuration, a multitude of fittings and accessories such as lights, massage jets, counter-current systems, and underwater loudspeakers are available.

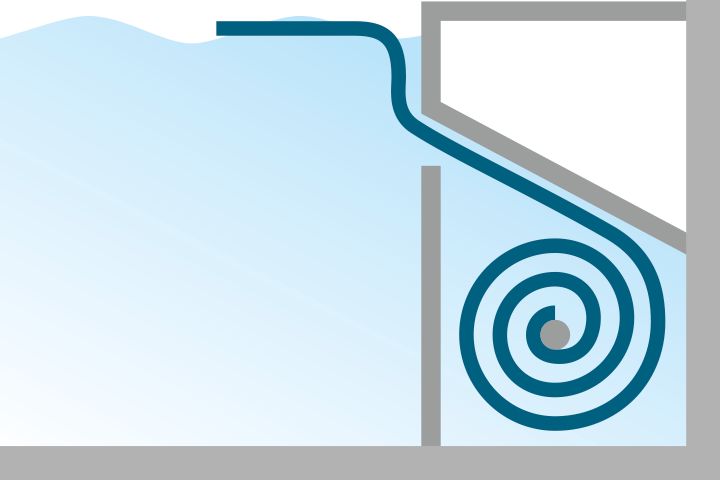

Overflow

Infinity

Skimmer

Edge staircase (with optional shallow area)

Full-width staircase

Corner staircase (round or straight)

Stainless steel ladder

Pool covers can be integrated to protect the pool against contamination and improve thermal insulation. In addition to the standard version, they can also be installed in a recess or with a bench function. The trending colours for the new generation of pools are various shades of grey. They are particularly suited for organic pools. Due to its natural look and excellent cleaning properties, Biotop recommends the colour blue-grey (RAL 7031).

Pool cover “chamber”

Pool cover “beach”

Pool cover “sitting ledge”